About Us

Professional power inductor, common mode choke, RJ45 and Transformer manufacturer

Coilmaster: Pioneering Efficiency and Innovation in Magnetics

Welcome to Coilmaster, where engineering excellence meets innovative solutions. As a professional manufacturer of inductors, common mode chokes, and transformers, we're dedicated to elevating energy efficiency and sustainability in the electronics industry. Our mission is simple yet ambitious: to craft high-performance magnetics that minimize energy loss and pave the way for a sustainable future.

Our team of skilled engineers thrives on designing power magnetics with superior efficiency. We're not just about products; we're about empowering our customers with exceptional service, irrespective of their business size. Our commitment extends beyond words—we've invested in fully automated production lines and established special fast-track production options to ensure swift delivery, proving our dedication to your success.

Furthermore, we hope could help customer to solve all the problem / difficulty in their design process. Because the experienced engineer team, we could design the customized core to meet various requirement. Furthermore, the flexibility service we had is to provide the different designing kits to designing engineer and support them from the small number of polit run testing to mass production. But you don’t have to wait like 15~20 weeks delivery date or wait the allocation from other giant manufacturer. The pilot order normally will work as reel quantity (SPQ). And after the trial production, we still could support 6~8 weeks lead time for mass production. And the MOQ is always available to discuss.

Engineering Excellence and Decades of Dedication

Since our inception in 1995, Coilmaster has been on a journey of growth and innovation. From our early days specializing in ferrite cores to becoming a magnetic industry authority, our passion for progress is unwavering. Our engineers' expertise in power magnetics design is at the heart of our operation, ensuring we meet your unique needs with precision and care.

Diverse Products, Unmatched Quality

Our commitment to quality is evident in our diverse product lineup, including high-performance power inductors, chokes, and LAN magnetics, tailored to meet and exceed your expectations. At Coilmaster, "zero defect" isn't just a slogan—it's our mindset, backed by significant investment in production and testing technology to guarantee excellence.

Your Reliable Magnetics Partner

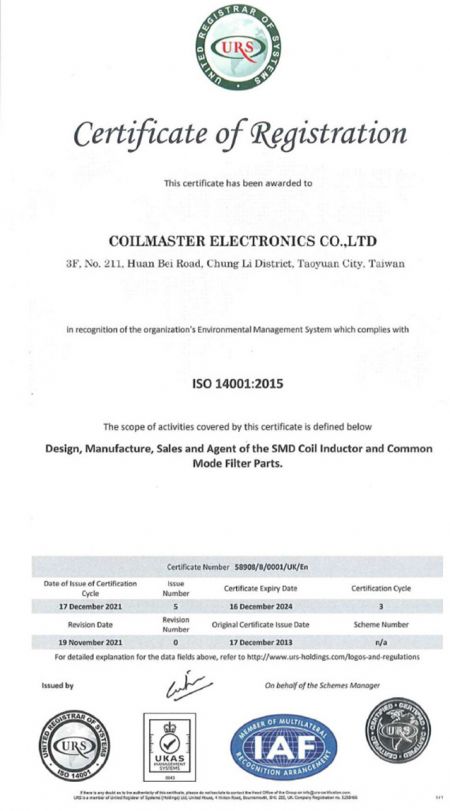

Choosing Coilmaster means more than just getting high-quality components. It means partnering with a team that supports you at every step, from design to delivery. Our certifications (IATF16949, ISO9001, ISO14001) and state-of-the-art reliability lab are testaments to our commitment to your success.

Sustainable Operations: Our Commitment to the Planet

Our dedication extends beyond technology to include a deep commitment to environmental sustainability. From solar-powered operations in Taiwan to water-saving initiatives and plans for eco-friendly upgrades in our China factory, we're dedicated to making a positive impact.

Let Coilmaster be your guide in the world of high-quality magnetics. Contact us to discover how our commitment to excellence, innovation, and sustainability can support your projects. Together, let's create a more efficient, sustainable future.

| Department | Overview of Responsibilities |

|---|---|

| Office of the General Manager | Mission: Spearheads long-term development and strategic planning, including annual business adjustments, environmental analysis, and management information dissemination. Formulates comprehensive business objectives, such as quality, and environmental policies. Oversees goal management, business analysis, new product development discussions, pricing strategies, and construction planning for new facilities. Prepares board proposals and monitors execution. |

| Audit Department | Mission: Conducts thorough audits of business plans, budget adherence, departmental performances, and various operational sectors including sales, procurement, production, and R&D. Recommends improvements for internal controls and manages legal affairs and contracts, ensuring organizational integrity. |

| Occupational Safety and Health Office | Mission: Dedicates to ensuring workplace safety through regulation research, educational programs, hazard prevention, and health management. Oversees safety protocol implementation and compliance, safeguarding employee well-being. |

| Management Division | Mission: Manages core operations including administration, procurement, IT, and plant affairs. Coordinates logistics, oversees investment management, and executes annual budgets, ensuring operational excellence across all divisions. |

| Administration Unit | Mission: Handles vital administrative functions such as document and asset management, recruitment, personnel administration, and public relations. Ensures a smooth operational flow and maintains a positive organizational image. |

| Information Unit | Mission: Oversees IT infrastructure, system maintenance, and information security. Supports production automation and communication systems, ensuring technological efficiency and security. |

| Procurement Unit | Mission: Manages procurement processes, controls costs, resolves material issues, and develops sourcing strategies. Ensures the timely acquisition of high-quality materials and equipment. |

| Plant Affairs Unit | Mission: Maintains and enhances facility operations, including construction, utilities, environmental controls, and safety equipment. Ensures operational efficiency and environmental compliance. |

| Finance Division | Mission: Oversees financial operations including budgeting, fund management, financial reporting, and tax declarations. Manages company assets and shareholder relations, ensuring financial health and compliance. |

- 1st floow Manual/Semi-automated working area

- 2nd floor automated production area (inductor)

- 2nd floor automated production area (inductor)-1

- 2nd floor automated production area (inductor)-2

- 2nd floor automated production area (inductor)-3

- 3rd floor automated production area (transformer)

- 3rd floor automated production area (transformer)-1

- 3rd floor automated production area (transformer)-2

- Certificates