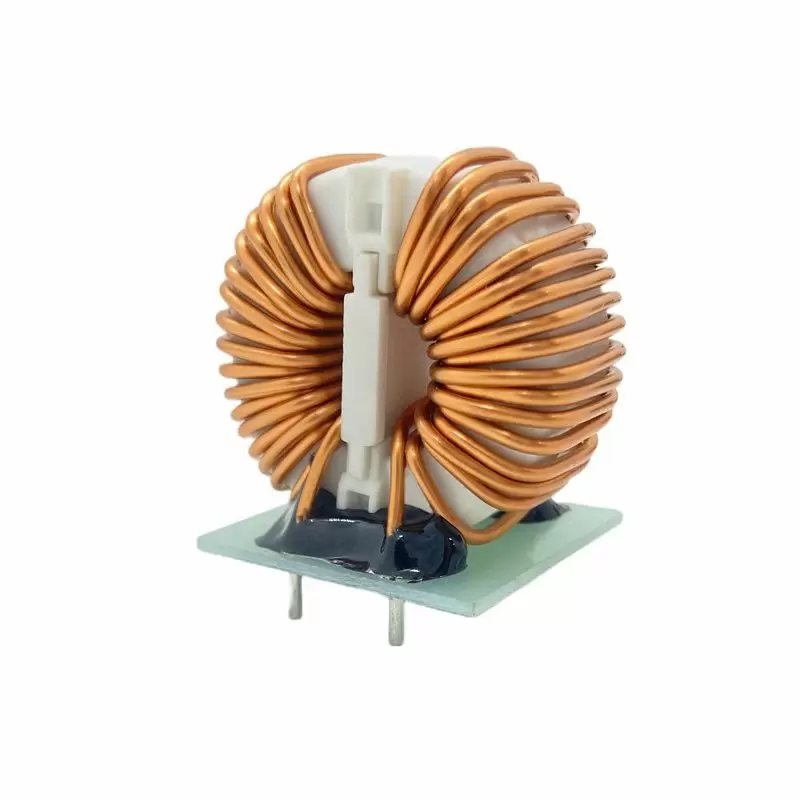

Miniature Wirewound Power Inductor(Ferrite)

High Power Density Ferrite SMD Wire-Wound Inductors, Shielded Option

Coilmaster’s Miniature SMD Wire-Wound Inductors utilize Ferrite Cores to achieve industry-leading Power Density, higher inductance, Low DCR, and Strong Saturation Current compared to ceramic or air-coil types. These components are essential for Compact DC-DC Converters, Power Supply Filtering, and High Q RF circuits. Advanced options include Magnetic Shielding to reduce EMI/crosstalk while maintaining superior Q factor and SRF.

Compared with non-magnetic ceramic-core inductors, Ferrite Wire-Wound Inductors offer greater Current Handling Capability and Inductance Density. Our engineering team specializes in optimizing Flux Leakage and frequency behavior by adjusting the Shielding Structure, ensuring the best balance between Q factor, SRF, and Stable Power Output for Switching Regulators.

Need Lower Flux Leakage, Higher Saturation Current, or specific Q/SRF targets? Coilmaster provides custom ferrite wire-wound inductors with: ✔ Optimizable Magnetic Shielding Design; ✔ Tight Tolerances down to ±2%; ✔ Engineering Support to match your circuit/frequency. ➜ Share your spec or schematic and our Power/RF team will propose the best option.

Customized Shielding & Tolerance Tuning Options

Some applications are magnetically sensitive, Coilmaster also provides non-ferrous cores products, such as ceramic or air-coil material. This will give you the low profile, high Q factor, and SRF (self-resonant frequency) value. The SMT miniature wire-wound inductors from Coilmaster have reliable quality due to the highly automated process. All of the products will be checked by the fully automated machine to reach our goal; zero defects. Furthermore, except for the standard part, a customized item is suitable for us.

Characteristic

Non-Magnetic Core Construction, Ultra-High Q Value, Highest SRF

Stable Performance at GHz

Immunity to External Magnetic Fields

Tight Tolerance ±2% available

Features

- High SRF & Q factor value

- Wide range operating temperature: -40 °C to +105 °C / +125 °C

- Highest possible saturation current based on ferrite

- Reflow soldering

- Wire wound on ferrite (ceramic is available)

Applications

- High Power Density DC-DC Converter Power Lines

- RF Tuner & Impedance Matching Networks

- Filter & High Gain Amplification Circuits

- Compact Switching Regulators

- Mobile/Portable Devices & 5G Telecom Modules

Miniature Wirewound Power Inductor(Ferrite) | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, Miniature Wirewound Power Inductor(Ferrite), common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.