Industrial & Energy Power Electronics

Industrial Power Electronics – Inductors, Chokes & Magnetics for Motor Drives, PLCs, and Energy Systems

Industrial and energy power systems demand exceptional stability, low power loss, and rigorous EMI control to withstand 24/7 operation, high temperatures, and harsh electrical environments. This hub serves as a technical guide for engineers to align application requirements—such as motor drives, PLC control units, and Solar/ESS platforms—with Coilmaster’s high-performance magnetic solutions.

Industrial and energy power electronics operate in significantly harsher environments than typical consumer devices. From factory automation and high-torque motor drives to solar inverters and grid-scale energy storage systems (ESS), every power stage must maintain predictable electrical behavior and thermal stability over a decade-plus service life.

This Industrial & Energy Hub is designed to help engineering teams navigate the complexities of magnetics selection, ensuring compliance with strict EMI standards and maximizing energy efficiency through advanced material science and structural design.

Critical Challenges in Industrial & Energy Power Design

Compared to general-purpose electronics, industrial platforms face extreme constraints regarding thermal management and electromagnetic compatibility (EMC).

- 24/7 Continuous Duty: Systems often run without downtime, making core losses (AC loss) and copper losses (DC loss) critical factors in preventing thermal runaway.

- High Current & Saturation: Compact cabinet designs require inductors with high current density and "soft saturation" characteristics to handle peak loads safely.

- Severe EMI/Noise Environments: High-speed switching (GaN/SiC) in modern inverters creates significant dv/dt noise, necessitating shielded magnetics to protect sensitive control logic.

- Environmental Robustness: Components must withstand thermal cycling, vibration, and humidity without mechanical or electrical degradation.

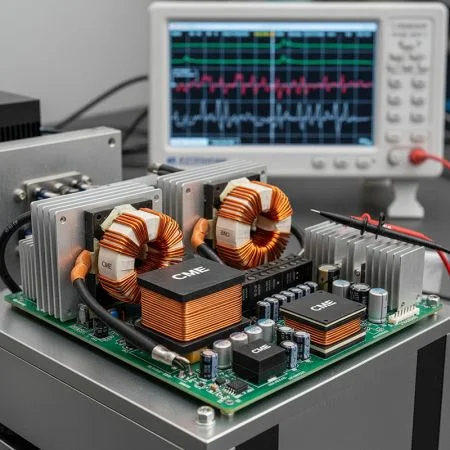

Core Magnetic Building Blocks in Industrial Architecture

Selection begins with understanding where the magnetics sit within the system architecture:

1. DC-DC Converters (Control & Aux Power)

Generating stable 24V, 12V, or lower voltage rails for PLCs, sensors, and I/O modules. Requires compact, low-noise power inductors.

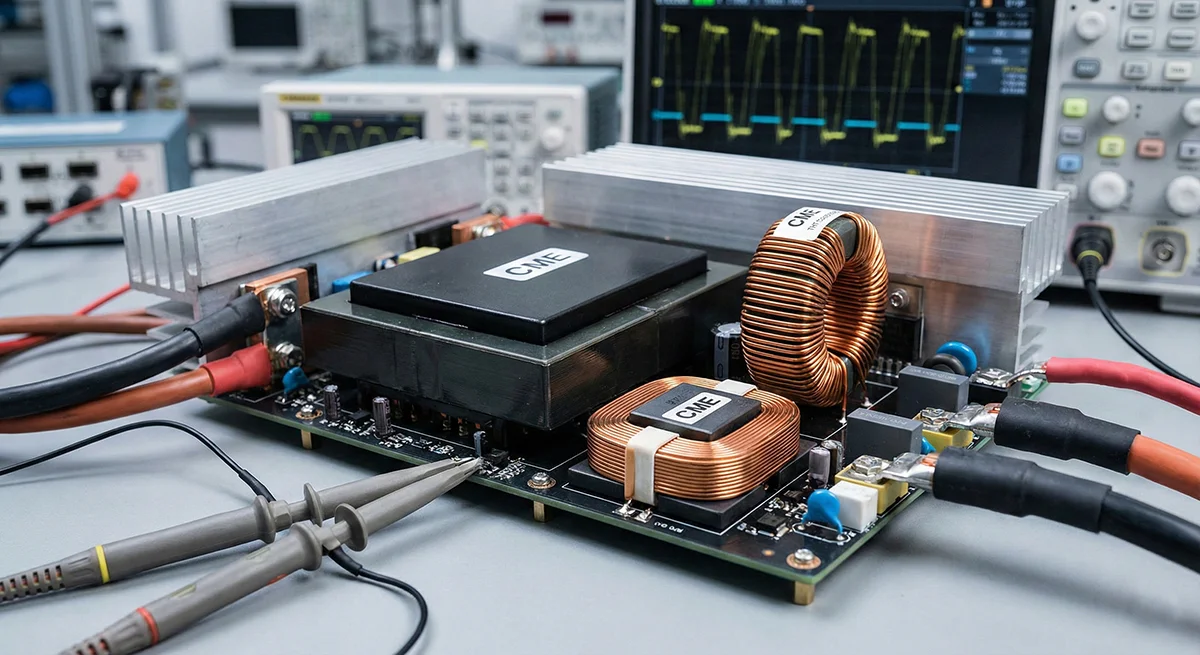

2. Motor Drives & Frequency Inverters

Managing high-power switching for industrial automation and robotics. Magnetics must handle high ripple currents and provide robust EMI filtering (Common Mode Chokes).

3. Solar Inverters & Energy Storage (ESS)

Focusing on maximum conversion efficiency. Requires low-DCR flat wire inductors and stable DC-bias performance to handle wide input voltage ranges.

Professional Selection Logic: Beyond the Datasheet

For industrial-grade reliability, magnetics must be evaluated under worst-case operating conditions, not just nominal specs.

- Thermal-Aware Saturation: Inductance drops as temperature rises. We provide saturation curves at elevated temperatures to ensure safety margins.

- DCR vs. Temperature Rise: Minimizing DCR is essential for enclosed or fanless designs where heat dissipation is limited.

- Magnetic Leakage Management: Our molded and shielded structures minimize stray magnetic fields that could interfere with nearby high-speed communication lines.

Recommended Magnetics Solutions

To assist engineers in rapid selection, we provide high-performance representative product series for core circuits in industrial and energy systems. While specific cores are listed as references, we support a wide range of magnetic materials to meet your specific design requirements.

1. Power Factor Correction (PFC Inductors) – TC Series

For AC-DC front-end circuits, our TC Series utilizes various core materials, including Sendust, MPP, High-Flux, and more. We are not limited to these materials; we can select the optimal core based on your switching frequency and efficiency targets to effectively improve the system power factor and meet stringent power quality regulations.

2. EMI Suppression (Common Mode Chokes) – CMT, SMM, UT, UU Series

Industrial noise environments are highly complex. We offer comprehensive solutions from Through-Hole (THT) to Surface Mount (SMD):

- THT Solutions (CMT, UT, UU Series): Ideal for high-power lines, providing high impedance and excellent heat dissipation.

- SMD Solutions (SMM Series): Specifically designed for power rails, handling high current loads within compact footprints.

- Technical Edge: Coilmaster can precisely adjust core materials to optimize the Impedance Curve based on your application, ensuring maximum EMI suppression at target frequencies.

3. Planar & Power Transformers – PE, EFD, EF, EI, EL, ERL Series

For isolated power conversion, we provide standard and customized transformer structures:

- Planar Transformers (PE Series): We offer standard Planar solutions for high-efficiency, low-profile designs. Custom specifications are available upon technical review and project-specific cost assessment.

- Traditional Structures (EFD, EF, EI, EL, ERL): Designed for high insulation (Hi-Pot) and low leakage inductance, widely used in gate drives and auxiliary SMPS.

4. Current Sensing – EE5.0 Series

Accurate monitoring is vital for Solar and ESS platforms. Our EE5.0 Series provides a compact transformer-based current sensing solution. We can evaluate and confirm other specifications to meet your specific system monitoring needs.

5. High-Current Power Inductors – SEP-EX, REP, SEP-EN Series

For high-efficiency DC-DC stages, we recommend our specialized power inductor series:

- Flat Wire Series (SEP-EX, REP Series): Featuring ultra-low DCR and superior current handling capabilities, these series are the best choice for reducing thermal stress in high-power motor drives and energy inverters.

- Molded Iron Powder Series (SEP, SEP-EN Series): These series offer excellent magnetic shielding and high-density packaging, ensuring controller stability and acoustic noise reduction in harsh industrial environments.

Key Application Segments

- Motor Drives & Robotics: Handling high dv/dt switching and harsh EMI.

- PLC & Factory Automation: Stable, long-life power rails for sensitive control circuits.

- Renewable Energy (Solar/Wind): High efficiency and EMC compliance for grid-tie systems.

- EV Charging Infrastructure: High power density and thermal stability for rapid charging stages.

Engineering Support & Customization

Coilmaster partners with your design team to reduce validation risks and accelerate time-to-market:

- Advanced DC-bias and thermal modeling.

- EMI suppression consultation and component matching.

- Customized footprint and electrical specs for optimized system performance.

Need a recommendation? Provide your Vin/Vout, switching frequency, and target current, and our engineers will provide a best-fit solution within 24-48 hours.

Technical FAQ

Why can't I use standard consumer-grade inductors in industrial power stages?

Consumer-grade components often lack the thermal stability and DC-bias margin required for 24/7 industrial duty. Industrial-grade inductors use specialized core materials and robust termination designs to ensure they don't fail under continuous thermal stress or high vibration.

How does "Soft Saturation" benefit industrial inverters?

Soft saturation (typical in molded metal powder cores) prevents a sudden drop in inductance during current spikes. This protects the switching MOSFETs/IGBTs from overcurrent damage and provides a wider safety margin during transient loads.

What is the advantage of Flat Wire technology in Energy Systems?

Flat wire increases the effective cross-sectional area of the conductor within the same window area. This drastically reduces DC Resistance (DCR) and skin effect losses, leading to higher efficiency and cooler operation in Solar and ESS applications.

- Related Products

2.2uH, 29A Molding Inductor With Flat Wire High Efficiency

SEP1010EX-2R2M-LF

Composite High Current Molded Flat Wire Power Inductors with flat cooper wire, SEP1010EX series (10mm height), which offers high current handling capacity,...

Details Add to List700uH, 3.5A High Current Toroidal Fixed Inductors

TC3312-701M-3.5A-LF

A toroidal power coil with a rating of 700uH and 3.5A is widely used in electronic circuits. It is an insulated coil that is wire wound on a ring-shaped...

Details Add to List3200uH 12Amps nanocrystalline EMI choke

CMT3010BNA-322-12A-LF

With a 3200 µH inductance rating and 12A continuous current capability, this nanocrystalline common mode choke is engineered for power line EMI reduction...

Details Add to List- Related FAQ

How does DC bias affect inductance stability in industrial DC-DC converters?

DC bias reduces the effective permeability of the magnetic core, causing inductance to drop as current increases. In industrial DC-DC converters with high...

Why is low DCR especially important in industrial and energy power inductors?

Low DC resistance minimizes copper losses, reducing heat generation and improving overall system efficiency. In continuously operating industrial and energy...

What EMI risks are unique to motor drives and inverter-based power systems?

Motor drives and inverters generate strong common-mode and differential-mode noise due to fast switching and large voltage transitions. Magnetic flux leakage...

Motor Drives & Inverters

Motor drives and industrial inverters operate with high switching energy, fast dv/dt edges, and large transient currents that stress magnetics far beyond...

Automation & PLC Power Rails

PLC and industrial automation platforms rely on stable, low-noise DC power rails to ensure the reliable operation of CPUs, I/O modules, and safety circuits....

Renewable Energy – Solar Inverters & ESS

Solar inverters and energy storage systems (ESS) demand high-efficiency, wide-voltage-range power conversion with strict EMI and safety requirements. This...