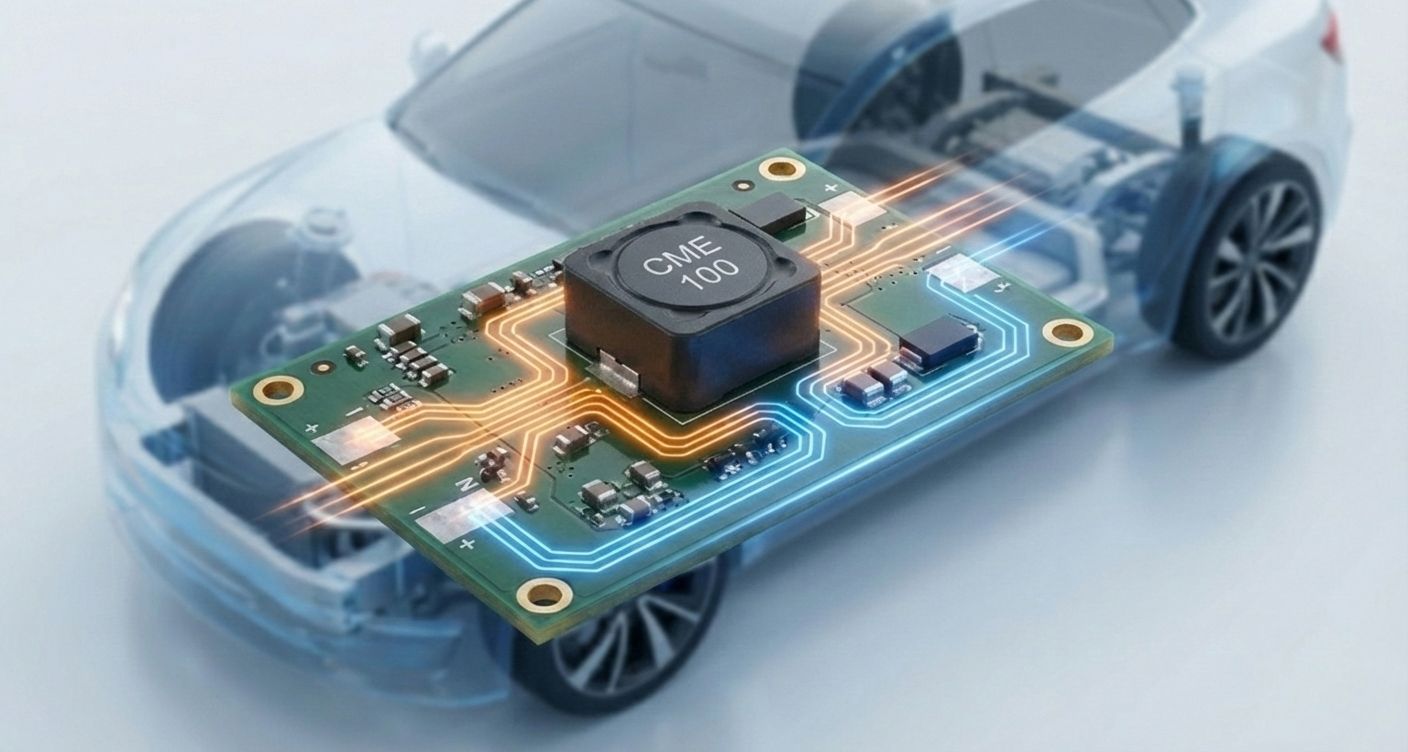

Automotive Power Inductors for DC-DC Power Conversion

Automotive grade power inductor, common mode choke and transformer

Automotive power inductors engineered for DC-DC power conversion across vehicle electronic systems, including ECU power rails, lighting systems (headlamps, matrix headlights, tail lamps, interior and ambient lighting), battery management systems (BMS), ADAS electronics, and in-vehicle networking.

This application hub provides a system-level overview of automotive DC-DC power challenges, selection logic, and design considerations under harsh vehicle operating conditions.

Overcoming Design Challenges in Automotive Power Electronics

Automotive DC-DC power stages operate under significantly harsher conditions than consumer or industrial electronics. Power inductors must deliver stable electrical performance over wide temperature ranges, continuous current stress, and long service lifetimes, while meeting strict automotive safety and EMC requirements.

- Thermal Stability – Automotive power circuits must maintain predictable inductance and efficiency from −40°C up to 125°C or higher, where core saturation and copper loss increase rapidly.

- EMI & EMC Compliance – Radiated and conducted noise must be tightly controlled to avoid interference with sensors, communication buses, and safety-critical vehicle electronics.

- Mechanical Robustness – Inductors must withstand vibration, mechanical shock, and repeated thermal cycling throughout the vehicle’s service life.

- High Current Density – Modern ECUs and power modules require compact inductors with low DCR to reduce heat generation and maximize conversion efficiency.

Automotive DC-DC Application Overview

Automotive DC-DC power conversion spans multiple functional domains within modern vehicles. This overview groups common use cases to provide a clear navigation framework for deeper technical guidance.

DC-DC converters for ECUs and control modules

Power conversion stages supplying electronic control units that require stable inductance under continuous load, compact size, and controlled EMI behavior.

Typical requirements: stable DC bias at temperature, fast transient response, compact footprint, and low EMI sensitivity.

Automotive lighting systems

DC-DC converters used in front and rear lamps, matrix and adaptive headlights, daytime running lights, ambient lighting, and cabin illumination.

Typical requirements: stable current regulation, low EMI to protect vehicle networks, and consistent brightness over temperature.

Battery Management Systems (BMS)

Safety-critical DC-DC stages operating continuously in battery monitoring and balancing systems.

Typical requirements: low loss for thermal control, stable inductance under DC bias, and long-term electrical reliability.

ADAS, camera, and sensor power supplies

Noise-sensitive DC-DC converters located near high-speed signal paths and RF modules.

Typical requirements: low magnetic flux leakage, predictable EMI behavior, and stable high-frequency performance.

Onboard auxiliary power rails and body electronics

High-volume DC-DC solutions for body control modules, actuators, and auxiliary subsystems.

Typical requirements: balanced cost, thermal stability, and consistent manufacturability.

Infotainment and in-vehicle networking power stages

DC-DC converters operating close to Ethernet, CAN, and multimedia interfaces.

Typical requirements: low noise, low leakage, and protection of signal integrity.

Selection Logic for Automotive DC-DC Power Inductors

When selecting power inductors for automotive DC-DC converters, evaluation should be performed at the system level rather than relying solely on nominal datasheet values.

Saturation Current at Operating Temperature

Inductor saturation current decreases as temperature rises. Automotive designs must evaluate DC bias performance at maximum operating temperature rather than room-temperature values.

DCR and Thermal Performance

Lower DCR reduces conduction losses and limits self-heating in compact, enclosed automotive housings.

Magnetic Shielding Structure

Shielded or molded constructions reduce magnetic flux leakage, improving EMI behavior in noise-sensitive vehicle electronics.

Mechanical and Environmental Reliability

Inductors must maintain stable electrical and mechanical performance under vibration, humidity, and thermal cycling over long vehicle lifetimes.

Why Coilmaster Automotive Power Inductors

Coilmaster automotive power inductors are designed for long-term reliability, electrical stability, and manufacturability in vehicle environments.

- AEC-Q200 qualified – validated for thermal shock, vibration, humidity, and automotive reliability stress.

- IATF 16949 certified manufacturing – controlled processes, consistent quality, and full traceability.

- Optimized core and winding structures – stable inductance under DC bias and reduced thermal stress.

- Responsive engineering support – fast design feedback during development, validation, and production ramp-up.

Engineering Support for Automotive DC-DC Designs

Coilmaster provides engineering support for automotive DC-DC power designs, including selection guidance, thermal considerations, and EMI behavior evaluation. Application-specific discussions and customization support are available to assist engineers during early design and validation stages.

- Related Products

22uH 8.8A Automotive Molding Power Choke

SEP1005T-220M-LF-A

Elevate your electronic systems to new heights with our latest innovation, the Automotive-Grade SMD Molded High Current Inductor. With dimension 11.0x10.0x5.2mm,...

Details Add to List1uH, 68Amps Automotive Surface Mount Flat Wire Low Loss Power Inductor

SER2013-1R0M-LF-A

Automotive grade high current SMD power inductors with flat cooper and AEC-Q200 qualified (grade 1) SER2013-A series, the peak current ratings up to 68 A at inductance...

Details Add to List100uH 2.4A Automotive Molded SMD Power Inductor

SEP0705T-101M-LF-A

Elevate your electronic systems to new heights with our latest innovation, the Automotive-Grade SMD Molded High Current Inductor. With dimension 7.9x7.2x5.2mm,...

Details Add to List- Related FAQ

What defines a power inductor as automotive-grade?

Automotive-grade power inductors are designed to operate reliably across wide temperature ranges and under mechanical stress. In addition to electrical...

Why are shielded inductors commonly used in automotive DC-DC designs?

Shielded inductors help limit magnetic flux leakage, reducing EMI risks in vehicle systems where power and signal circuits operate in close proximity.

How do automotive operating environments differ from industrial DC-DC applications?

Automotive environments combine wide temperature ranges, continuous vibration, long service lifetimes, and strict EMC requirements, placing higher demands...