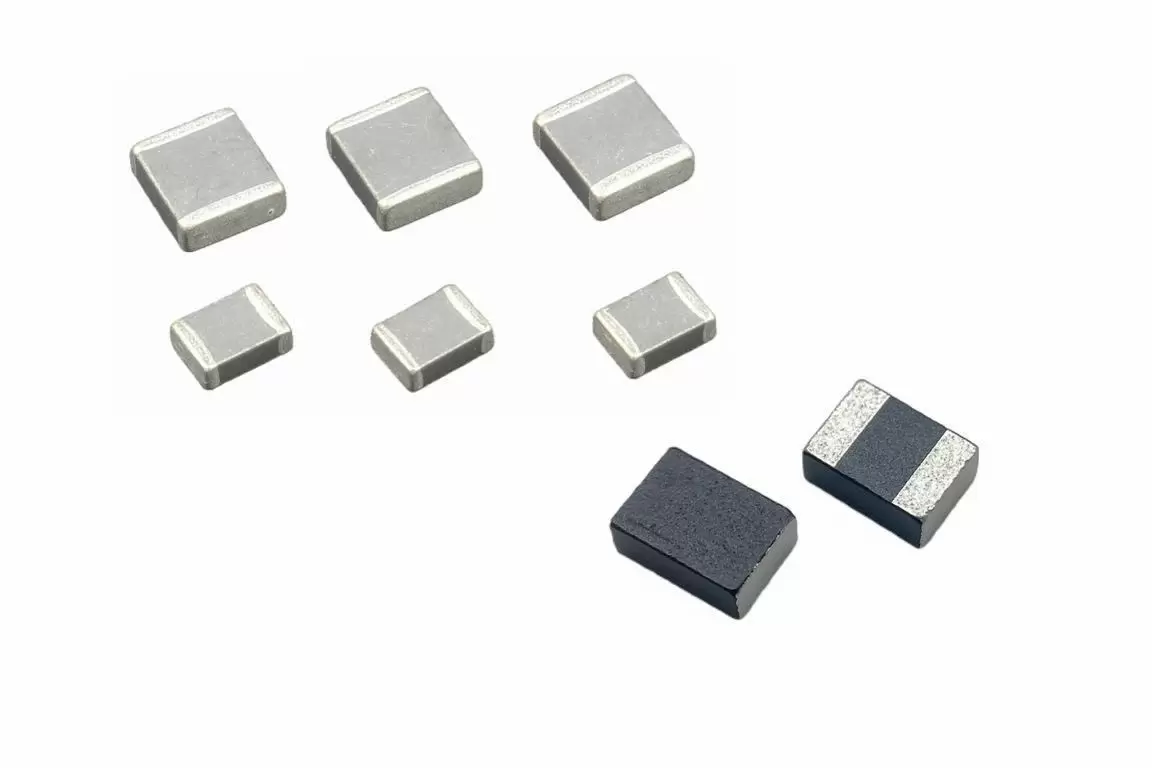

Multilayer Ferrite Power Inductors

High-Current Multilayer Ferrite Power Inductors for Compact DC-DC Converters (Low DCR)

Multilayer ferrite power inductors are designed for compact power circuits where high current capability, low profile, and stable inductance are required. While multilayer structures are traditionally used for EMI filtering, advancements in ferrite materials and internal conductor technology now allow these inductors to support significantly higher saturation current (Isat) and rated current (Irms) values. These components offer a space-saving alternative to wire-wound power inductors in applications where PCB area is limited, yet performance requirements remain demanding.

Miniature, high-current multilayer ferrite inductors engineered for DC-DC converters, portable devices, and space-restricted power circuits.

* Other surface-mount miniature inductors you may also consider:

Need higher Q for RF filtering/tuning? → Multilayer RF Chip Inductors [URL: /en/category/CAT-Ceramic_Multilayer_Chip_Inductors.html]

Need GHz-class stable inductance for precision RF matching? → Thin-Film RF Chip Inductors [URL: /en/category/CAT-Ceramic_Thin_Film_Chip_Inductors.html]

Need EMI filtering on signal/power lines? → Multilayer Ferrite Chip Beads [URL: /en/category/CAT-Ferrite_Multilayer_Chip_Beads.html]

Need stronger magnetic shielding or significantly higher Isat? → Molded Power Inductors [URL: /products/molded-power-inductors]

Multilayer vs. Hot-Pressed Ferrite Technology (Manufacturing Comparison)

Two manufacturing technologies are used in compact ferrite power inductors: multilayer ceramic construction and hot-pressed ferrite technology. Hot-pressed types achieve higher inductance and greater freedom in customized geometries, while multilayer types remain ideal for ultra-compact footprints with stable characteristics. Coilmaster offers sizes from 0603 (1608) up to 1210 (3225) to satisfy different power density requirements.

High-Current Capability from Miniature Packages

Characteristic

* High saturation current (I

sat) and high Irms in compact SMD sizes.

Low DCR for improved conversion efficiency.

Stable inductance across load changes (High anti-saturation).

Ferrite core optimized for power applications.

Copper internal winding improves thermal handling and pulse reliability.

Available in 0603, 0805, 1008, 1210 sizes.

Excellent mechanical strength and reflow compatibility.

RoHS / REACH compliant.

Features

- Space-saving alternative to wire-wound inductors.

- Ideal for portable electronics and high-density PCB layouts.

- Enhanced transient-response performance in DC-DC converters.

- Supports fast-switching power ICs.

- Tight inductance tolerance for predictable power behavior.

- Strong anti-vibration and thermal robustness.

Applications

- Step-down / step-up DC-DC converters.

- Smartphones, tablets, wearable devices.

- Power rails for CPUs, PMICs, and IoT modules.

- High-density portable electronics.

- Battery-powered devices with limited PCB space.

- POL (Point-of-Load) regulators.

- LED drivers and low-voltage power stages.

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 0.24uH, 2.6A Multilayer chip inductor | 1.6x0.8x0.8 | 0.24 | 3.2 | 2.6 | 54 | |

| 0.33uH, 2.2A Multilayer power inductor | 1.6x0.8x0.8 | 0.33 | 3 | 2.2 | 75 | |

| 0.47uH, 1.6A Multilayer power chip inductor | 1.6x0.8x0.8 | 0.47 | 2.2 | 1.6 | 100 | |

| 1uH, 1.5A Multilayer ferrite powder power inductor | 1.6x0.8x0.8 | 1 | 1.5 | 120 | ||

| 2.2uH, 1A Ferrite chip inductors | 1.6x0.8x0.8 | 2.2 | 1 | 200 | ||

| 4.7uH, 0.8A Ferrite power inductors | 1.6x0.8x0.8 | 4.7 | 0.8 | 250 | ||

| 10uH, 0.09A Multilayer inductor | 1.6x0.8x0.8 | 10 | 0.09 | 900 | ||

| 0.047uH, 0.05A 0603 Multilayer chip inductor | 1.6x0.8x0.8 | 0.047 | 0.05 | 300 | ||

| 0.068uH, 0.05A 0603 Multilayer power inductor | 1.6x0.8x0.8 | 0.068 | 0.05 | 300 | ||

| 0.082uH, 0.05A 0603 Multilayer power chip inductor | 1.6x0.8x0.8 | 0.082 | 0.05 | 300 | ||

| 0.1uH, 0.05A 0603 Multilayer ferrite powder power inductor | 1.6x0.8x0.8 | 0.1 | 0.05 | 500 | ||

| 0.12uH, 0.05A 0603 Ferrite chip inductors | 1.6x0.8x0.8 | 0.12 | 0.05 | 500 |

Multilayer Ferrite Power Inductors | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, Multilayer Ferrite Power Inductors, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.