Automation & PLC Power Rails

Automation & PLC Power Rails – Low-Noise, High-Reliability Inductors & Magnetics for Industrial Control Systems

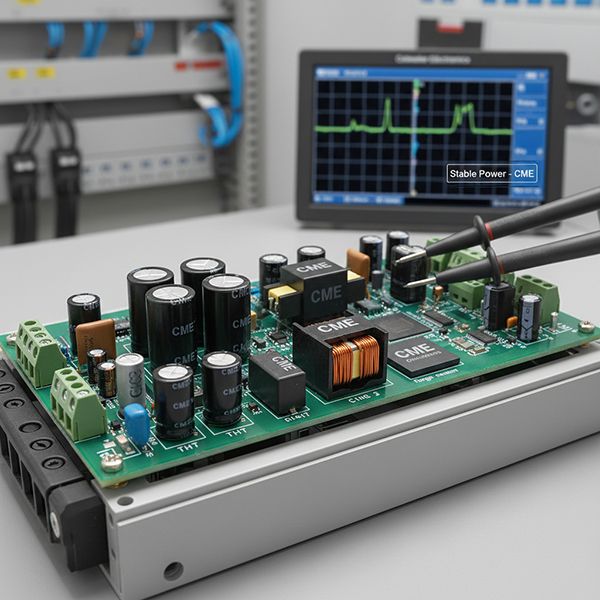

PLC and industrial automation platforms rely on stable, low-noise DC power rails to ensure the reliable operation of CPUs, I/O modules, and safety circuits. This page explains how to address EMI and thermal challenges using Coilmaster’s SEP-EN, SMM, and EE5.0 series magnetics, optimized for long-term stability and minimal electromagnetic interference in sensitive control environments.

PLC and industrial automation systems depend on clean, stable DC power rails to support CPUs, I/O modules, communication interfaces, and safety circuits. Even micro-fluctuations in voltage or electromagnetic noise can lead to false triggering, data corruption, or unexpected system resets.

This Automation & PLC Power Rails hub focuses on maximizing signal integrity through advanced magnetic shielding and stable DC-bias performance. We highlight how Coilmaster structures—such as molded inductors and precision chokes—support the 24/7 reliability required for modern smart factories.

Why Control Power Rails Are Different in PLC Systems

Unlike high-power motor drives, PLC power rails prioritize low ripple and high noise immunity to protect sensitive semiconductor components.

- Noise-Sensitive Loads: CPUs, ADCs, and fieldbus transceivers require ultra-low ripple to maintain data accuracy.

- 24/7 Continuous Operation: Industrial controllers must operate for decades, requiring inductors with minimal aging effects and predictable thermal behavior.

- Compact Enclosures: High power density in DIN-rail or rack-mount formats demands magnetics with excellent heat dissipation and small footprints.

- Strict EMC Compliance: Control cabinets must adhere to rigorous conducted and radiated emission standards (e.g., EN 61131-2).

Typical PLC Power Architecture & Magnetic Zones

Industrial automation controllers typically utilize a multi-stage regulation strategy:

1. Input EMI Filtering Stage

Using Common Mode Chokes (SMM or UU series) to prevent switching noise from leaking back into the 24V/48V factory power bus.

2. Main DC-DC Conversion Stage

Generating the core 12V, 5V, or 3.3V rails. This stage requires high-reliability molded inductors (SEP-EN series) for stable energy storage.

3. Isolated Auxiliary & Communication Power

Providing galvanic isolation for RS485, CAN bus, or Ethernet interfaces using compact EFD/EF transformers or EE5.0 series for current monitoring.

Professional Selection Logic for Control Power

For PLC systems, magnetics are evaluated for shielding effectiveness and DC-bias stability:

- Shielded/Molded Efficiency: Molded structures (like SEP-EN) confine magnetic flux, preventing interference with nearby high-speed signal traces.

- Predictable Inductance: Since PLCs often run at constant loads, maintaining stable inductance under DC-bias ensures loop stability and prevents voltage sag.

- Thermal Drift Control: Low-DCR designs minimize heat buildup inside sealed control cabinets, extending the life of nearby electrolytic capacitors.

Recommended Coilmaster Solutions for Automation

We recommend the following series for achieving industrial-grade stability in control power designs:

1. Molded Power Inductors – SEP-EN & SEP Series

Our SEP-EN Series is the premier choice for PLC power rails. Its metal-molded structure provides superior magnetic shielding and high saturation current in a compact form factor, significantly reducing acoustic noise and EMI.

2. Power Rail Common Mode Chokes – SMM & UU Series

For suppressing conducted emissions on 24V DC inputs, the SMM (SMD) and UU (THT) series offer high impedance to block high-frequency noise while handling the full load current of the controller.

3. Isolated Auxiliary Transformers – EFD, EF, & EE Series

We provide a wide range of small-form-factor transformers (EFD15, EFD20, EF12.6) for isolated flyback converters. The EE5.0 Series is also available for compact current sensing and feedback loops.

4. Point-of-Load (POL) Regulation

For local regulation near CPUs and FPGAs, our small-size molded inductors ensure clean power delivery with minimal board space consumption.

Typical Design Questions in PLC Power Rails

- Noise Margin: How much ripple and EMI can the CPU and I/O tolerate?

- Thermal Drift: Will inductance or DCR shift over years of continuous operation?

- EMC Risk: Which power paths are most likely to fail conducted-emission tests?

- Layout Sensitivity: Are magnetics close to analog or high-speed digital circuits?

Engineering Support

Coilmaster supports automation projects with magnetics optimized for noise immunity and long-term stability.

- DC-bias and thermal drift evaluation for the SEP-EN series.

- Customized Impedance Curve tuning for SMM/UU chokes to pass EMC testing.

- Custom transformer designs (EFD/EF) for specialized isolation voltages or auxiliary rails.

Technical FAQ

Why are PLC power rails more sensitive to noise than power inverters?

PLC systems contain CPUs, ADCs, and communication ICs that can be affected by very small voltage ripple or magnetic interference. Noise that would be harmless in a motor drive can cause data errors or false triggering in control circuits.

Why are shielded inductors preferred in control power supplies?

Shielded or molded inductors confine magnetic flux inside the core, reducing the risk of EMI coupling into nearby signal traces, sensors, and communication lines.

Why does DC bias stability matter for PLC DC-DC converters?

PLC converters often operate at nearly constant load. If inductance drops significantly under DC bias, control-loop stability and output ripple can degrade over time.

- Related Products

1320uH, 3.3A Power line SMD choke

SMM1710BHP-132-LF

1320uH, 3.3A Power line SMD choke, this SMD common mode choke with dimension 19.5x17.0x10.0mm featurs with high rated current and high impedance suitable...

Details Add to List700Ω, 10A Power line SMD choke

SMM1513-701-LF

700Ω, 10A Power line SMD choke, this SMT common mode line filter with dimension 15.5x13.0x6.3mm featurs with high rated current and high impedance suitable...

Details Add to List20A EE5 Sensing transformer

EE5XFS-202-LF

The EE5XFS-202-LF current sense transformer is a highly efficient and compact transformer exclusively designed for current sensing applications. Its exceptional...

Details Add to List- Related FAQ

Why is thermal stability more important than peak current rating?

PLC systems run continuously for years. Small thermal drift can accumulate and affect regulation accuracy and long-term reliability.

How do common-mode chokes help in PLC cabinets?

They prevent noise from traveling between the PLC and the factory power bus, reducing EMC failures and interference between cabinets.

What EMC standards usually drive PLC power design?

Industrial PLCs often must meet IEC 61000-6-2 and IEC 61000-6-4 for immunity and emissions.