Motor Drives & Inverters

Motor Drives & Inverters – High-Performance Power Inductors, EMI Chokes & Magnetics for VFD, Servo, and SiC/GaN Inverter Stages

Motor drives and industrial inverters operate with high switching energy, fast dv/dt edges, and large transient currents that stress magnetics far beyond typical DC-DC converters. This page summarizes the key EMI and thermal challenges in VFD/servo inverter stages, explains selection logic under real operating conditions, and highlights the SEP-EX, REP, and TC series used for high-efficiency power conversion and conducted-noise suppression.

Motor drives and industrial inverters (VFD / servo drives) are among the harshest environments for power magnetics. High current ripple, fast dv/dt switching from modern SiC/GaN power modules, and strong common-mode noise can quickly expose weaknesses in thermal stability and saturation margin.

This Motor Drives & Inverters hub provides engineering teams with a clear selection logic—covering EMI choke impedance strategies, inductor loss trade-offs, and recommended Coilmaster product families designed to survive 24/7 industrial operation.

Motor Drive & Inverter Power Design Challenges

Inverter stages face significantly higher switching energy and stronger EMI coupling paths compared to general-purpose power supplies.

- High dv/dt and Common-Mode Noise: Fast switching edges generate strong common-mode currents that drive EMC failures in control logic and encoders.

- Transient and Peak Currents: Motor start/stop and torque steps produce current spikes that can lead to inductor saturation if the margin is insufficient.

- Thermal Gradients: Components must maintain stable inductance even under high self-heating within sealed or fanless industrial cabinets.

- Long-Term Reliability: Magnetic characteristics must remain stable over years of temperature cycling and vibration.

Where Magnetics Sit in a Typical Motor Drive

Selection begins with identifying the stress mechanism of each functional zone:

1. EMI Input Filtering (EMC Compliance)

Using Common Mode Chokes to reduce conducted noise (150kHz–30MHz) returning to the supply and protecting nearby sensitive sensors.

2. DC-Link & PFC Stage

Utilizing high-power PFC inductors (TC Series) to improve power factor and handle high DC-link voltages.

3. Inverter Bridge & Auxiliary Power

Managing high ripple current in the phase legs and providing isolated power for gate drivers using Planar (PE Series) or EFD/EF transformers.

Professional Selection Logic for Inverters

Safeguard your design by evaluating magnetics under "Worst-Case" operating conditions:

- Thermal-Aware Saturation: We provide DC-bias curves at elevated temperatures to ensure inductance remains stable during motor torque transients.

- AC Loss vs. Switching Frequency: With the rise of high-frequency SiC inverters, selecting low-core-loss materials is critical to avoid hot spots.

- Impedance Curve Matching: For CMCs, the impedance peak must align with the inverter’s noise spectrum. "Highest impedance" is not always the best; "Targeted impedance" is the goal.

Recommended Coilmaster Solutions for Inverters

Based on industrial field data, we recommend the following structures for motor drive platforms:

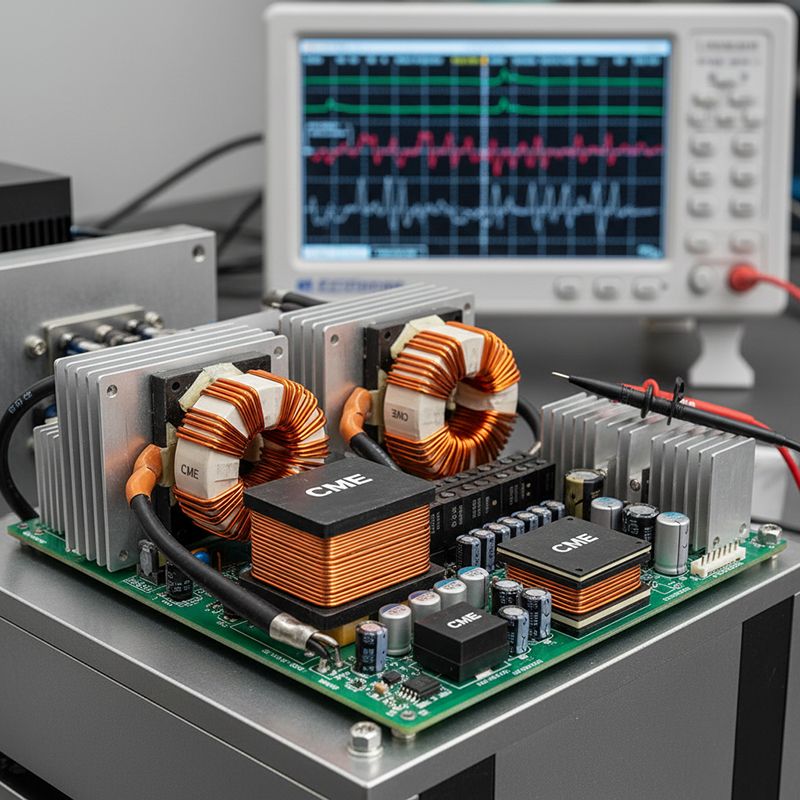

1. Ultra-Low DCR Power Inductors – SEP-EX & REP Series

Our Flat Wire SEP-EX and REP Series are engineered for high-power stages. The flat wire structure drastically reduces DC resistance and skin effect losses, providing a superior thermal margin during continuous peak-load operation.

2. High-Performance PFC Inductors – TC Series

Utilizing Sendust or MPP cores, the TC Series is optimized for high-frequency PFC stages, ensuring stable inductance and low core loss across wide input voltage ranges.

3. EMI Chokes with Optimized Impedance – CMT, SMM, UT, UU Series

Available in both THT and SMD, these series can be customized with specific core materials to match your inverter's noise signature. We support custom Impedance Curve tuning to solve difficult EMC failures.

4. High-Frequency Isolated Transformers – PE & EE5.0 Series

Our PE Series Planar Transformers offer ultra-low profiles and high efficiency for gate-drive power, while the EE5.0 Series provides compact current sensing for phase current monitoring.

Typical Design Questions Engineers Validate

- EMC Readiness: Which noise bands are failing (150kHz–30MHz) and how should the choke impedance curve be positioned?

- Thermal Margin: What is the worst-case temperature rise at continuous torque and at transient peaks?

- Current Spikes: What peak current occurs during start/stop/regeneration and how much inductance drop is acceptable?

- Layout Sensitivity: Are sensor/communication lines exposed to leakage field from inductors or chokes?

Engineering Support

Coilmaster supports motor-drive projects with selection guidance and evaluation under application conditions.

- DC bias and inductance stability review at operating temperature

- Choke impedance-curve tuning guidance for conducted-noise suppression

- Loss trade-off recommendations (DCR vs. core loss vs. switching frequency)

- Customization support for footprint, impedance targets, and mechanical constraints

If you share your DC-link voltage, switching frequency, target current (RMS/peak), and EMC target band, we can recommend a best-fit structure quickly.

- DC bias and thermal stability review for SEP-EX/REP series.

- Choke impedance-curve tuning for CMT/SMM series to meet CISPR/EN standards.

- Customization for PE Series Planar Transformers to fit specific isolated power requirements.

Related FAQ

Why do motor drives and inverters create stronger EMI than many other industrial power systems?

Inverter phase-leg switching produces fast dv/dt edges and large common-mode currents. This noise can couple through parasitic capacitance into cables, chassis, and control circuits, making conducted and radiated EMI more difficult to control than in many low-power DC-DC systems.

How should a common-mode choke be selected for an inverter input filter?

Selection should start from the inverter noise spectrum and EMC target band. The choke’s impedance curve must provide effective attenuation where noise is dominant, while also meeting current, temperature rise, and insulation requirements under continuous operation.

Why can two inductors with the same datasheet inductance behave differently in a motor drive?

Motor drives stress inductors with temperature rise, DC bias, and ripple current simultaneously. Core material, structure, and loss characteristics determine inductance drop and heating behavior, so real operating-condition evaluation is essential for stable performance.

- Related Products

100uH 8.9A high efficiency inductor

REP2918B-101M-LF

Our high-current flat wire DIP inductors are designed with a ferrite core for exceptional efficiency and low core loss. Capable of handling up to 8.9 amps...

Details Add to List153uH Planar flyback transformer

PE40R1-4421-LF

PE40R1-4421-LF ,the planar magnetics transformer is specifically designed for high-power applications that prioritize a low profile and low losses. In comparison...

Details Add to List3.5uH, 37A 1890 SMD Flat Wire High Current Indcutor

SEP1809E-3R5M-LF

Shielded Flat Wire High Current Inductor, SEP1809E series (9.2mm height), which offers high current handling capacity, low DC resistance and low power...

Details Add to List- Related FAQ

How should current rating be interpreted for motor drive magnetics?

Datasheet current ratings may not reflect inverter ripple and real thermal conditions. Designers should consider RMS current, peak transient current, allowable...

What information is most useful to recommend a magnetics solution for motor drives?

Key inputs include DC-link voltage range, switching frequency, phase current (RMS and peak), target inductance or impedance band, operating ambient temperature,...