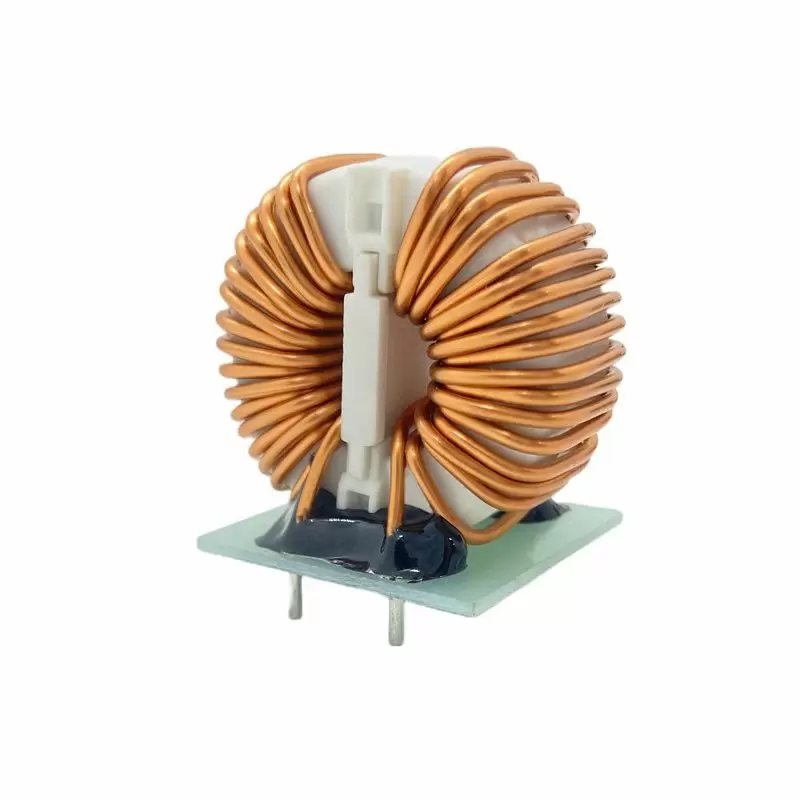

High Current Flat Wire Inductor

Flat-Wire Power Inductors: Ultra-Low DCR & Maximum Thermal Performance

Flat wire power inductors use rectangular copper wire to reduce copper loss, providing up to 40–60% larger surface area compared with traditional round-wire windings. This structure significantly lowers DC resistance, improves thermal dissipation, and enables higher continuous current capability under compact volume.

The design supports both molded and assembled structures, allowing engineers to balance efficiency, mechanical robustness, and voltage endurance based on application needs.

Key Advantages

Best current density per footprint

Excellent temperature performance for compact DC-DC stages

Longer operating life for assembled flat-wire models

Lower copper loss at high frequency

Ideal For Efficiency-Driven Systems

Features

- 40–60% larger effective conductor surface area

- Ultra-low DCR

- High thermal stability

- Supports low profile designs

Applications

- High-Power Buck / Multiphase VRM for Servers and GPU Regulators

- Automotive DC-DC Regulators (Efficiency-Driven)

- 5G Base Station Power and Telecom Equipment

- High-Density Power Modules requiring Max Current Density

- Electric Vehicle (EV) Traction Inverters and High-Power Systems

- Compact Industrial Controllers and Power Supplies

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 4.7uH, 32A Flat Wire Molded Surface Mount Power Inductors | 17.8x16.8x8.0 | 4.7 | 32 | 26.5 | 5.16 | |

| 5.3uH, 31A SMD Flat Wire Power Choke | 17.8x16.8x8.0 | 5.3 | 31 | 26 | 5.34 | |

| 6.2uH, 31A SMD Flat Wire Molding Choke | 17.8x16.8x8.0 | 6.2 | 31 | 23 | 6.5 | |

| 7.2uH, 29A Flat Wire Molding Power Choke | 17.8x16.8x8.0 | 7.2 | 29 | 21 | 7.2 | |

| 8.2uH, 25A Surface Mount Molding Power Inductors With Flat Wire | 17.8x16.8x8.0 | 8.2 | 25 | 19 | 7.92 | |

| 10uH, 21A SMD High Current Molding Power Chokes | 17.8x16.8x8.0 | 10 | 21 | 16 | 9.6 | |

| 15uH, 18A High Performance Molded Power Inductor | 17.8x16.8x8.0 | 15 | 18 | 13 | 15 | |

| 22uH, 16A Molding Inductor With High Efficiency | 17.8x16.8x8.0 | 22 | 16 | 12 | 23.2 | |

| 4.7uH, 39A SMD Molded Inductor With Soft Saturation | 17.8x16.8x10 | 4.7 | 39 | 30 | 3.8 | |

| 5.6uH, 34A High Saturate Current Molding Power Inductor | 17.8x16.8x10 | 5.6 | 34 | 28 | 4.2 | |

| 6.8uH, 31A Molding Power Choke | 17.8x16.8x10 | 6.8 | 31 | 26 | 4.6 | |

| 8.2uH, 28A Fixed Inductor With High Saturate Current | 17.8x16.8x10 | 8.2 | 28 | 25 | 7.2 |

High Current Flat Wire Inductor | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, High Current Flat Wire Inductor, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.