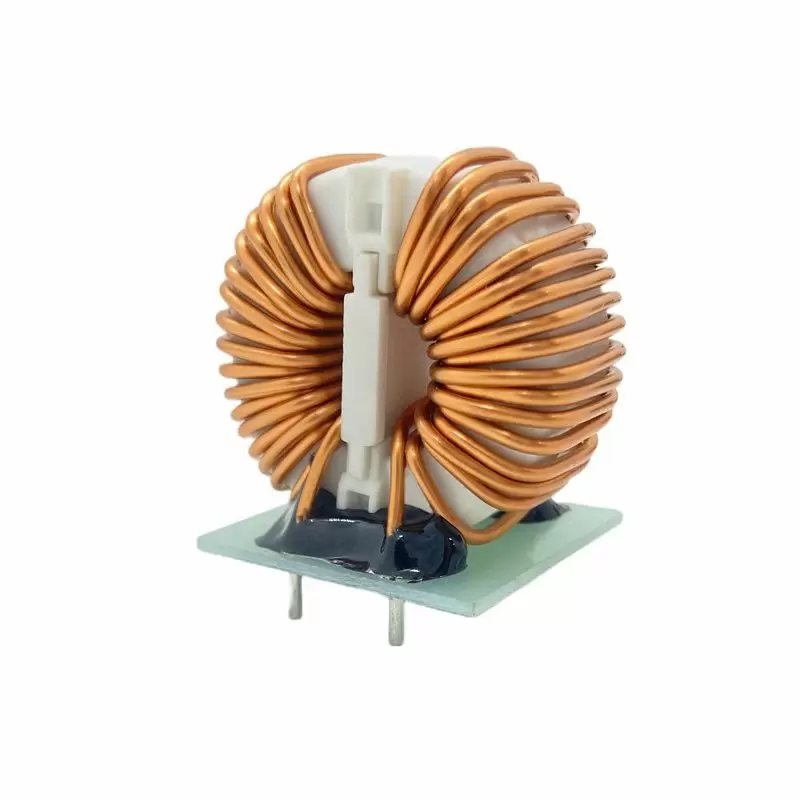

2 mH, 10 A common mode choke designed for renewable energy inverter applications

CMT2010BNA-202-LF

Tailored 2 mH / 10 A nanocrystalline choke solutions to solve EMI challenges

Introducing our advanced nanocrystalline common mode chokes from the CMT2010BNA family, designed to deliver reliable EMI suppression for high-power and space-constrained applications. With their robust construction and compact form factor, these chokes are well-suited for demanding sectors such as automotive electronics, renewable energy, and precision industrial control systems. Their optimized design ensures stable performance, even in harsh thermal environments, making them an excellent choice for next-generation power solutions.

This model provides an inductance of 2 mH with a continuous current capability of 10 A, packaged in a practical 24 × 17 × 25 mm housing. The design emphasizes low losses and high efficiency, enabling engineers to minimize thermal stress while maintaining compliance with stringent EMI standards. Beyond standard performance, we offer the ability to fine-tune electrical parameters such as impedance and current handling to match specific design challenges. This flexibility ensures smooth integration across diverse platforms while providing a balance of performance and cost-effectiveness.

Choosing our nanocrystalline chokes means securing more than just a component — it means benefiting from tailored engineering support and long-term reliability. Our team collaborates closely with customers to resolve EMI bottlenecks, reduce development risks, and accelerate time to market. Whether for automotive-grade durability or optimized power electronics performance, this 2 mH, 10 A solution offers the reliability and adaptability needed to stay competitive in a rapidly evolving industry.

Customization

Due to the solid background of our engineer team at ferrite powder territory, we could modify the core powder, design and produce the most suitable product to fit customer's applications. Except for the standard characteristic of our series specification, Coilmaster Electronics also offer the customization product with low minimum order quantity (MOQ), tighter tolerance, different inductance and frequency applications.

Leadtime

Coilmaster’s standard lead time is 6~8 weeks, in urgent case, the fast delivery program is available. For specific product series, we could send out the goods within 10 or 20 working days.

Key features

- Very high permeability nanocrystalline core material

- Improved isolation through plastic case and winding spacer

- High and stable inductance values up to 150 °C

- High rated currents

- Broadband suppression

- Small size

- Frequency range: 1 kHz-300 MHz

- Flammability corresponding to UL 94 V-0

Applications

- Power electronics

- Power line in- and output filter

- Filtering of devices without any ground connection

- Suppression of radio interferences in motors

- Suppression of common mode noise

Construction

- Common Mode Choke

Size(mm)

- 24.0x17.0x25.0

Inductance(uH)

- 2000

Inductance tolerance

- ±50%

Test Frequency(MHz)

- 0.01

Irms(A)

- 10

DCR(mΩ)

- 6.3

Additional Notes

Hi-Pot : 1500 (V)

NOMINAL VOLTAGE

VAC : 300 (V)

- Related Product

Custom impedance choke engineered for EMI compliance with 9 mH and 5 A rating

CMT2010BNA-902-LF

Discover the CMT2010BNA Series Nanocrystalline Common Mode Power Line Chokes, engineered for high-performance...

Details Add to List10000uH, 3A Horizontal common mode chokes

CMT2510B-103N-LF

10000uH, 3A Power line filter, CMT2510B series with the dimension 31.0x37.80mm. Utilize the T core...

Details Add to List6.8uH, 31A Molding Power Choke

SEP1510EX-6R8M-LF

Fixed inductor with high saturate current, SEP1510EX series (10mm height), which offers high...

Details Add to List- Download

2 mH, 10 A common mode choke designed for renewable energy inverter applications | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 2 mH, 10 A common mode choke designed for renewable energy inverter applications, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.

.jpg?v=c2f4fa7b)

.jpg?v=5e13ddeb)