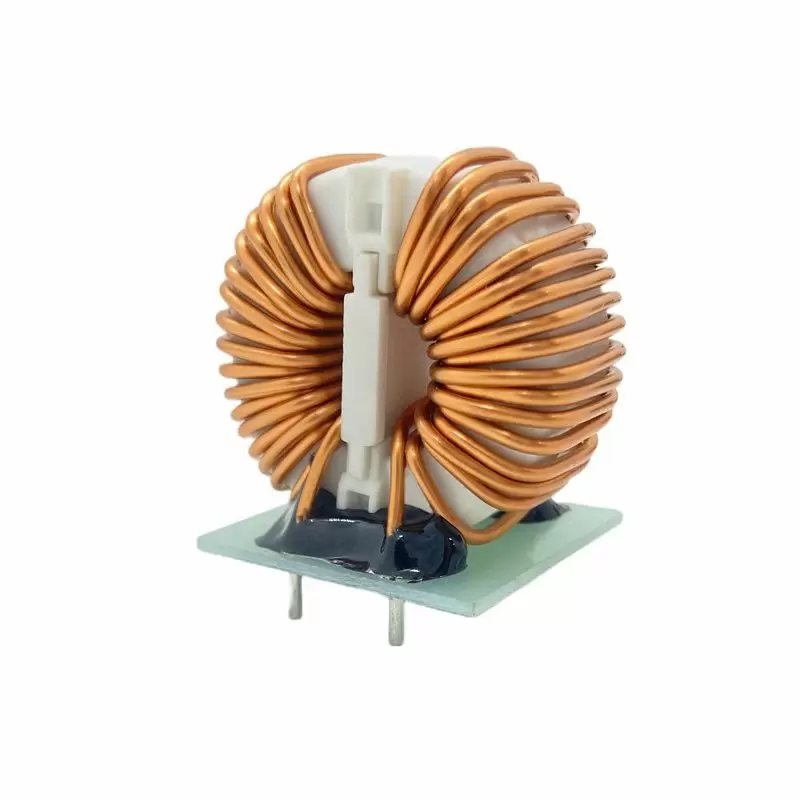

7 mH 7 A High-Current Nanocrystalline Common Mode Choke

CMT2214BNA-702-7A-LF

High-current design with low DCR and stable EMI control up to 150 °C.

Engineered for industrial drives, power modules, and high-current automation systems, the 7 mH / 7 A CMT2214BNA provides reliable EMI suppression without excessive heat generation. Its compact size supports demanding layouts while ensuring compliance with industrial EMC standards.

Unlike conventional amorphous chokes, it leverages nanocrystalline core technology and a reinforced winding structure to deliver both low DCR and superior thermal balance. This ensures stable EMI attenuation even under continuous 7 A operation, reducing the risk of overheating in compact designs.

The 7 mH / 7 A model is tested for sustained performance up to 150 °C, giving engineers confidence in long-term reliability. Its balance of high current density, low losses, and vibration resistance makes it the ideal choice for compact yet powerful industrial and communication systems.

Customization

Due to the solid background of our engineer team at ferrite powder territory, we could modify the core powder, design and produce the most suitable product to fit customer's applications. Except for the standard characteristic of our series specification, Coilmaster Electronics also offer the customization product with low minimum order quantity (MOQ), tighter tolerance, different inductance and frequency applications.

Leadtime

Coilmaster’s standard lead time is 6~8 weeks, in urgent case, the fast delivery program is available. For specific product series, we could send out the goods within 10 or 20 working days.

Key features

- Low DCR design reduces thermal stress under 7 A continuous load

- Nanocrystalline core for high-frequency EMI suppression

- Reliable operation up to 150 °C with reinforced winding structure

- Compact form factor ideal for space-constrained layouts

Applications

- Industrial drives and motor controllers

- Communication power modules

- Automotive high-current systems

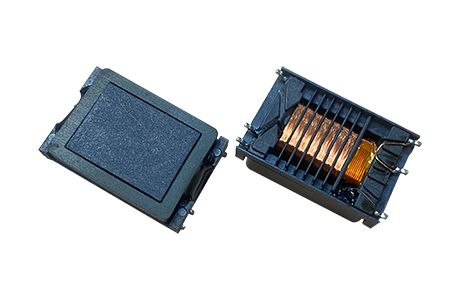

Construction

- Common Mode Choke

Size(mm)

- 30x19x28

Inductance(uH)

- 7000

Inductance tolerance

- ±50%/30%

Test Frequency(MHz)

- 0.01

Irms(A)

- 7

DCR(mΩ)

- 22

Additional Notes

Hi-Pot : 1500 (V)

Rated Voltage : 250 (V)

- Related Product

4000µH 11A Nanocrystalline Common Mode Choke for EMI

CMT2214BNA-402-11A-LF

The 4mH / 11 A CMT Series choke is tailored for communication power supplies and automotive...

Details Add to List4.7uH, 20A Automotive Molded SMD Inductor With E-Field Shield

SEP1004ECS-4R7M-LF-A

4.7uH, 20A Automotive Molded SMD Inductor With E-Field Shield is specifically designed to provide...

Details Add to List48uH CCFL transformer

EFD15XF-2F-LF

The CCFL transformer plays a crucial role in generating the high-voltage output necessary for igniting...

Details Add to List- Download

7 mH 7 A High-Current Nanocrystalline Common Mode Choke | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 7 mH 7 A High-Current Nanocrystalline Common Mode Choke, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.

.jpg?v=c2f4fa7b)