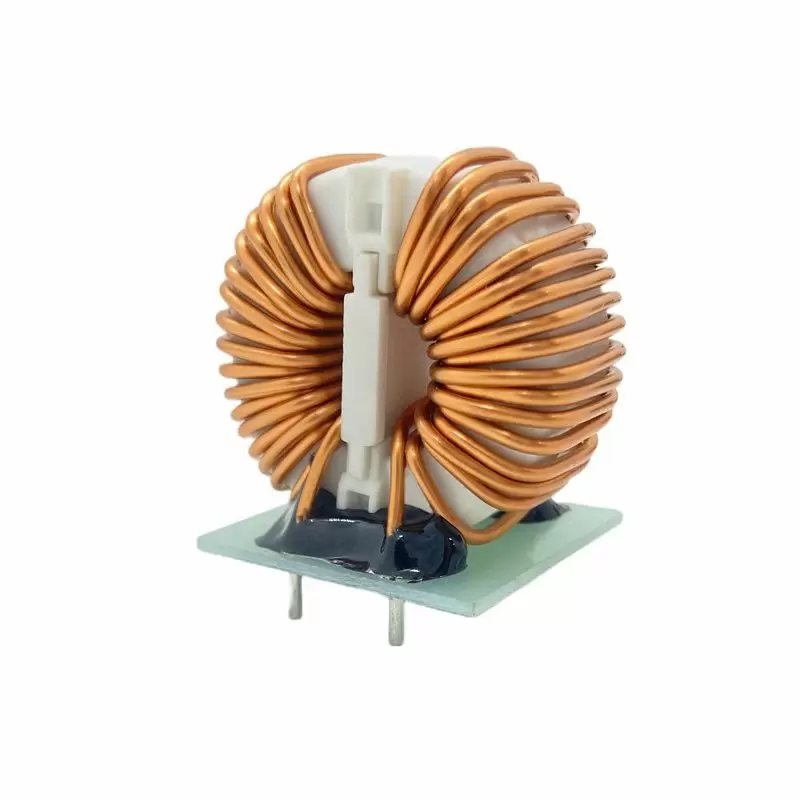

230uH 16A Mn-Zn ferrite common mode choke with center-post air gap design for adjustable inductance

CMT2711-231-LF

230uH 16A Air-gapped Mn-Zn common mode inductor optimized for adjustable inductance and high-current EMI filtering

This 230uH 16A common mode choke is designed for power systems that prioritize high current capability and thermal stability. Built with a gapped Mn-Zn ferrite core, it supports applications where noise suppression must remain consistent even under heavy load conditions. The 27.5 × 25 × 10.4 mm form factor makes it suitable for compact control units, high-power driver circuits, and industrial platforms that require dependable common-mode filtering without sacrificing available current headroom.

To support higher operating current, this version uses a reduced inductance value, resulting in a lower overall impedance profile compared with higher-uH variants. Even with the lower Z characteristics, it still provides meaningful wideband attenuation—about 26 dB at 2 MHz and around 21 dB at 100 MHz—making it effective for suppressing common-mode interference across mid- to high-frequency bands. The optimized air-gap design ensures stable magnetic performance under high load and minimizes inductance drift during heavy current operation.

With its 16A current rating and balanced Mn-Zn ferrite structure, this common mode choke is well-suited for power supplies that demand stronger thermal headroom and stable EMI control. It helps manage conducted noise in switching stages, LED lighting systems, and compact industrial controllers where higher current throughput is required. The controlled leakage inductance also enhances differential-mode filtering, providing a dependable solution for designs that need a practical mix of high-current capability and mid-band EMI suppression.

Customization

Due to the solid background of our engineer team at ferrite powder territory, we could modify the core powder, design and produce the most suitable product to fit customer's applications. Except for the standard characteristic of our series specification, Coilmaster Electronics also offer the customization product with low minimum order quantity (MOQ), tighter tolerance, different inductance and frequency applications.

Leadtime

Coilmaster’s standard lead time is 6~8 weeks, in urgent case, the fast delivery program is available. For specific product series, we could send out the goods within 10 or 20 working days.

Key features

- High-current capability

- Robust mechanical construction

- Consistent EMI performance under load

- Low-profile through-hole package

Applications

- Wideband EMI attenuation: ~20 dB @ 2 MHz and ~17 dB @ 100 MHz

- Thermally stable magnetic behavior under long-duration high load

- Balanced dual-winding structure for consistent common-mode suppression

- Mn-Zn ferrite core with controlled air-gap for stable high-current inductance

Construction

- Common Mode Choke

Size(mm)

- 27.5x25x10.4

Inductance(uH)

- 230

Inductance tolerance

- ±40%

Test Frequency(MHz)

- 0.1

Irms(A)

- 16

DCR(mΩ)

- 3.6

Additional Notes

Hi-Pot : 1500 (V)

Rated Voltage : 250 (V)

- Related Product

100uH, 1.35A Wirewound Shielded Surface Mount Inductor

SDC105R-101N-LF

100uH, 1.35A Wirewound Ferrite Shielded SMD Inductors with dimension 10.3x10.5x5.1mm. The SMD magnetically...

Details Add to List47uH, 0.66Amps Radial Lead cost effective shielded power inductor

RDS664D-470M-LF

Radial lead shielded power choke RDS664D series provide the rugged, economical and shielded...

Details Add to List1170uH, 1.22A SMD common mode line filter low frequency

SMM1710BHP-112-LF

1170uH, 1.22A SMD common mode line filter low frequency, this SMD common mode choke with dimension...

Details Add to List- Download

230uH 16A Mn-Zn ferrite common mode choke with center-post air gap design for adjustable inductance | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 230uH 16A Mn-Zn ferrite common mode choke with center-post air gap design for adjustable inductance, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.