High Current Power Line SMD Common Mode Choke

Surface-Mount High-Current Common-Mode Filters (Low DCR, Power Line)

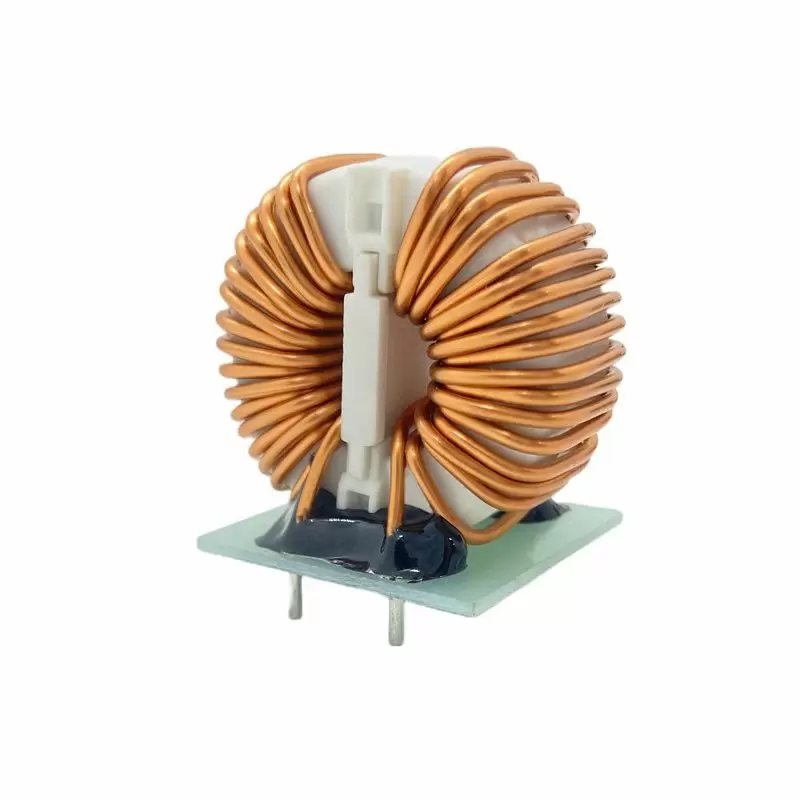

Coilmaster’s SMM series is a high-current surface-mount common-mode choke designed for power-line filtering in AC-DC and DC-DC converter systems. Using optimized T-core ferrite structures, specialized winding methods, and low-DCR construction, these chokes provide excellent common-mode noise suppression while maintaining low temperature rise and high efficiency. Suitable for automotive and industrial power circuits requiring compact size and strong EMC robustness.

SMD wire-wound common-mode chokes for power lines must handle higher current, minimize losses, and maintain stable impedance across low to mid frequencies. The SMM series uses MnZn or custom ferrite cores with optimized winding structures to achieve: • High inductance for low-frequency noise • Low DCR for reduced heat generation • High Saturation Current capability • Strong thermal performance for continuous current applications. Coilmaster also offers matching SMD and through-hole CMC solutions for high-speed data lines, signal lines, and high-power converters.

How to Choose a High Current Common Mode Choke

Several factors should be considered when selecting a high-current SMD common-mode choke: Impedance Value – Higher impedance increases noise attenuation but narrows the effective frequency range. Typical measurements are done at 100 MHz; select based on required suppression band. Frequency Range – NiZn cores work better at high frequencies; MnZn cores deliver higher inductance for low-frequency filtering (<1 MHz). Package Size & DCR – Larger packages typically support higher current and lower DCR. Select based on thermal performance and available PCB area.

Key Advantages of T-Core Power CMC

Characteristic

High current capability

Ultra-low DCR design

MnZn & NiZn ferrite options

T-core construction

Wide operating frequency range 40°C to +125°C operation

Features

- Effective power-line EMI suppression

- Supports AC-DC & DC-DC converter filtering

- Low DCR and excellent thermal stability

- SMD compact size for space-limited designs

- Stable impedance at low to mid frequencies

Applications

- Power supply circuits (AC-DC / DC-DC)

- Adapters, chargers, battery management units (BMS)

- Automotive ECUs and onboard power networks

- Industrial controllers, inverters, motor drivers

- General EMI suppression for high-current rails

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 11uH, 1.6A Low profile SMD common mode EMI chokes | 9.2x6.0x5.0 | 11 | 1.6 | 80 | ||

| 25uH, 1A Miniature SMT common mode filter | 9.2x6.0x5.0 | 25 | 1 | 160 | ||

| 40uH, 0.9A Low profile SMD common mode filter | 9.2x6.0x5.0 | 40 | 0.9 | 250 | ||

| 50uH, 0.8A Low profile SMD common mode EMI filters | 9.2x6.0x5.0 | 50 | 0.8 | 320 | ||

| 250uH, 1.2A SMD common mode choke coil | 9.2x6.0x5.0 | 250 | 1.2 | 130 | ||

| 470uH, 1.1A High impedance common mode choke | 9.2x6.0x5.0 | 470 | 1.1 | 140 | ||

| 500uH, 1A Miniature SMD common mode choke | 9.2x6.0x5.0 | 500 | 1 | 150 | ||

| 1000uH, 0.8A SMD ring core common mode choke | 9.2x6.0x5.0 | 1000 | 0.8 | 310 | ||

| 2000uH, 0.6A Surface mount CMC | 9.2x6.0x5.0 | 2000 | 0.6 | 420 | ||

| 4700uH, 0.4A Dual 1:1 SMD CMC Filters | 9.2x6.0x5.0 | 4700 | 0.4 | 900 | ||

| 6500uH, 0.3A Low profile SMD common mode EMI filters | 9.2x6.0x5.0 | 6500 | 0.3 | 1050 | ||

| 10uH, 2.5A Low profile SMD sectional winding common mode filter | 11.2x9.1x5.6 | 10 | 2.5 | 25 |

High Current Power Line SMD Common Mode Choke | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, High Current Power Line SMD Common Mode Choke, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.