Signal / Data Line SMD Common Mode Choke (NiZn / MnZn Ring Core)

NiZn/MnZn Toroidal SMD Chokes for Data Line & Power Line EMI Suppression

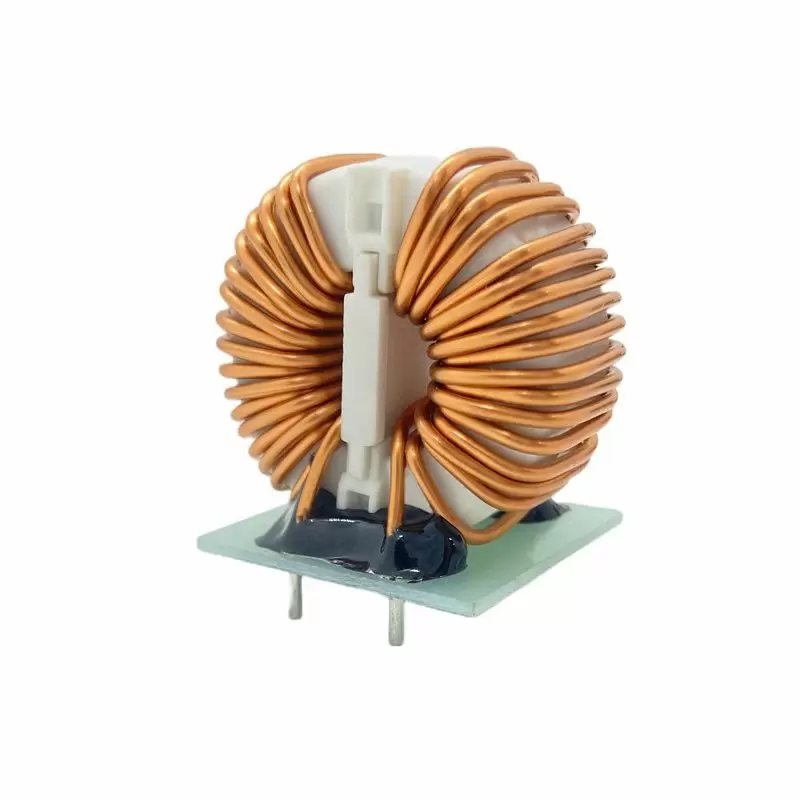

Coilmaster’s SMD common-mode filters with toroidal (ring) cores use a compact T-core structure with dual windings, making them suitable for both data lines and power lines. By selecting either MnZn or NiZn ferrite material, these chokes provide optimal common-mode impedance across different frequency ranges. MnZn delivers higher inductance and stronger noise suppression at low frequencies (EMI), while NiZn supports high-frequency applications such as high-speed data transmission. This construction ensures stable EMC performance in compact SMD footprints.

Power-line common mode chokes often require high isolation (Hi-Pot), high inductance, and higher current capability for DC/DC or AC/DC filtering. These designs typically use sectional winding to increase insulation strength (up to 2000 Vrms). For high-speed signal or data lines, isolation is less important, and bifilar winding is used to minimize differential-mode attenuation (Insertion Loss) and maintain signal integrity. Coilmaster’s SMD ring-core series operates from –40°C to +125°C, up to 80 VDC, and is fully compatible with reflow soldering.

Power-line vs Signal-line Selection Guide

• Power-line filtering (MnZn) – Higher inductance & impedance – Up to 2000 Vrms isolation (Sectional Winding) – Suitable for AC/DC, DC/DC, chargers, adapters

• Signal-line filtering (NiZn) – High-frequency noise suppression – Low insertion loss on differential signals (Bifilar Winding) – Ideal for CANBus, USB, HDMI, LVDS, MIPI

Toroidal Winding Advantages

Characteristic

MnZn & NiZn options

High inductance or high-frequency performance

Sectional or bifilar winding

Up to 2000 Vrms Hi-Pot Isolation

Low-Profile SMD design

Features

- Low-profile SMD footprint

- High impedance for effective EMI suppression

- Selectable winding structure for isolation or signal integrity

- Wide frequency coverage from kHz to GHz

- Reflow-compatible, –40°C to +125°C operation

Applications

- Power-line EMI filtering (AC-DC, DC-DC)

- Signal-line noise suppression (USB, HDMI, LVDS)

- Automotive CAN/LIN/FlexRay communication

- Industrial controllers & PLC systems

- Communication devices & I/O interfaces

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 51uH, 0.3A Low profile SMD common mode EMI chokes | 6.5x3.6x2.0 | 51 | 0.3 | 160 | ||

| 82uH, 0.3A Miniature SMD common mode filter | 6.5x3.6x2.0 | 82 | 0.3 | 200 | ||

| 100uH, 0.3A Low profile SMD common mode filter | 6.5x3.6x2.0 | 100 | 0.3 | 220 | ||

| 180uH, 0.3A Low profile SMD common mode EMI filters | 6.5x3.6x2.0 | 180 | 0.3 | 250 | ||

| 220uH, 0.3A SMD common mode choke coil | 6.5x3.6x2.0 | 220 | 0.3 | 280 | ||

| 330uH, 0.3A High impedance common mode choke | 6.5x3.6x2.0 | 330 | 0.3 | 300 | ||

| 11uH, 0.3A Miniature SMD common mode choke | 6.3x3.6x3.5 | 11 | 0.3 | 180 | ||

| 22uH, 0.3A SMD ring core common mode choke | 6.3x3.6x3.5 | 22 | 0.3 | 230 | ||

| 33uH, 0.3A Surface mount CMC | 6.3x3.6x3.5 | 33 | 0.3 | 270 | ||

| 51uH, 0.3A Dual 1:1 SMD CMC Filters | 6.3x3.6x3.5 | 51 | 0.3 | 320 | ||

| 100uH, 0.3A SMD low profile common mode choke | 6.3x3.6x3.5 | 100 | 0.3 | 580 | ||

| 470uH, 0.3A Surface Mount Power Line Common Mode EMI Chokes | 6.3x3.6x3.5 | 470 | 0.3 | 350 |

Signal / Data Line SMD Common Mode Choke (NiZn / MnZn Ring Core) | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, Signal / Data Line SMD Common Mode Choke (NiZn / MnZn Ring Core), common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster offers AEC-Q200 certified, high-efficiency power inductors, chokes, and transformers. Specializing in low-loss, high-current components for Automotive, 5G, and Industrial applications. Contact our experts for instant support. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.