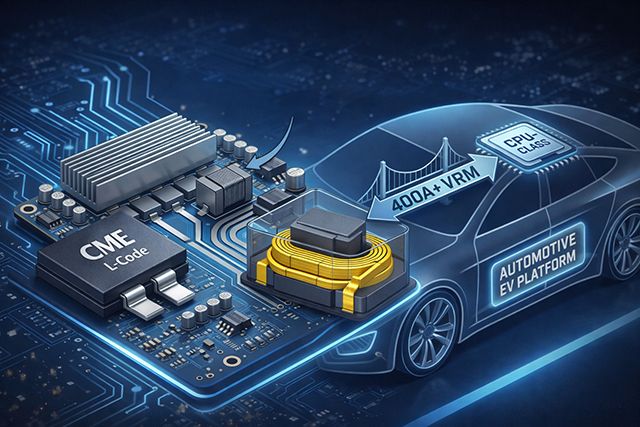

Bridging the Gap: Implementing 400A+ CPU-Class VRMs into Automotive EV Platforms

Engineering Solutions: Bridging the Gap — 400A+ CPU-Class VRMs for EV Platforms (SBP × SEP)

A system-level engineering solution that bridges CPU/GPU-class VRM magnetics into EV compute platforms by combining SBP ultra-low inductance copper-strip structures (dynamic di/dt control + DCR tuning) with SEP metal-composite inductors (energy backbone for Vdroop stability) under harsh AEC-Q200 operating environments.

EV compute platforms (ADAS/AD SoCs and high-performance infotainment processors) are shifting automotive power rails into CPU/GPU-class VRM territory: sub-1V operation, multi-phase architectures, and 200A–400A+ transient demand. The challenge is managing extreme load transients (high di/dt) inside harsh automotive environments where traditional wire-wound inductors struggle with higher DCR, slower response, and hard-saturation collapse. This hub presents a two-stage magnetic architecture: SBP as the “current frontier” for transient/inrush control and DCR tuning, and SEP/SEP-EX as the “energy backbone” to keep voltage stable during large load steps.

The Conflict: Traditional Automotive Inductors vs. EV Compute Rails

- Traditional automotive DC-DC rails were built around higher voltage and moderate current, where µH-level inductors and wire-wound structures are typically sufficient.

- Modern EV compute rails (ADAS/AD SoCs, AI accelerators, infotainment processors) operate below 1V yet demand 200A–400A+ with aggressive transient performance.

- This creates a clear technology gap: automotive-grade robustness must coexist with CPU-class VRM current density.

| Rail type | Voltage | Transient demand | Typical magnetics |

|---|---|---|---|

| Traditional automotive rails | 5–12V | Low–moderate | Wire-wound, µH-level |

| EV compute VRM rails | 0.6–1.2V | Extreme (high di/dt) | nH-level VRM magnetics |

The Challenge: High di/dt + AEC-Q200 Environment (Why Wire-Wound Falls Short)

- The core challenge is controlling extreme load transients (high di/dt) while maintaining stability and reliability under -40°C to +125°C, vibration, and long-life duty cycles.

- In this regime, traditional wire-wound inductors may fail to deliver stable behavior due to:

| Failure driver | What happens | System consequence |

|---|---|---|

| Higher DCR | Large I·DCR drop and I²R heating | Vdroop, thermal stress, efficiency loss |

| Hard saturation behavior | L(I) collapses abruptly near peak current | Overshoot/undershoot, protection trips, resets |

| Slower dynamic response | µH-scale inductance not optimized for CPU-class steps | Cannot meet tight ±5% rail window at sub-1V |

The Architecture: SBP (Dynamic Response) + SEP (Energy Backbone)

- EV compute VRM stability requires a two-stage magnetic architecture that separates responsibilities:

| Stage | Platform | Primary job | What it solves |

|---|---|---|---|

| Stage 1 | SBP (ultra-low L, copper-strip) | Dynamic response (di/dt control) | Inrush spikes, current surge, transient interference |

| Stage 2 | SEP / SEP-EX (metal-composite) | Energy backbone (Vdroop control) | Voltage stability during large load steps (target: 0.8–1.0V within ±5%) |

- SBP enables higher switching frequency and faster transient response by operating at nH-level inductance (current-domain control).

- SEP / SEP-EX provides stable energy buffering with soft saturation to maintain usable L(I) under peak conditions (energy-domain stability).

SBP “Current Frontier”: Copper-Strip + Ultra-Low ESL Design

- SBP technology originated in CPU/GPU VRMs to survive nanosecond-class load steps and extreme current density.

- Its copper-strip structure supports ultra-low ESL (Equivalent Series Inductance) and stable geometry for repeatable performance.

- Unlike conventional coils, SBP is designed to act as a current-programming magnetic element—controlling how fast current can ramp during transient events.

Why it matters in EV compute modules

- High power density requirements demand fast current response without runaway inrush.

- Ultra-low L/ESL magnetics help the control loop respond quickly at high switching frequenc

Multi-Path Copper Architecture: Current Sharing Under 400A+ Demand

- Multi-path SBP structures use multiple copper strips to distribute current and reduce stress per conduction path.

- This improves thermal behavior and reduces saturation risk during peak events.

| Engineering concern | Multi-path effect | Benefit |

|---|---|---|

| Peak current surge | Splits current across parallel strips | Lower hotspot risk |

| Magnetic flux density | Reduces flux concentration per path | Lower saturation collapse probability |

| Thermal management | More copper surface couples to PCB planes | Better heat spreading than round-wire coils |

DCR Tuning for Multi-Phase VRMs: Preventing Current Imbalance

- In multi-phase VRMs, DCR mismatch between phases causes current imbalance, leading to localized overheating and reduced reliability.

- Many VRM controllers use DCR current sensing (V = I × DCR) instead of shunt resistors for efficiency and layout simplicity.

Challenge

- If DCR is too low or inconsistent, the sensed signal becomes noise-sensitive and phase balancing degrades.

Solution (SBP 1+2Pad advantage)

- SBP copper-strip geometry provides high consistency and low deviation, enabling stable DCR windows for current sensing and phase balancing.

- This supports stable current sharing—critical for EV compute rails under sustained high load.

%20PAD%20(L).jpg)

Data Evidence: Traditional vs. VRM-Grade Magnetics (What Engineers Compare)

| Metric | Traditional automotive inductor | SBP (VRM-grade, nH) | SEP / SEP-EX (energy backbone, µH) |

|---|---|---|---|

| Inductance range | 10–100µH | 100–500nH | 0.47–10µH (typical) |

| Primary role | General filtering / energy storage | di/dt + inrush control | Vdroop stability / energy buffer |

| Saturation behavior | Often hard-cliff | Designed for high peak | Soft saturation (usable L(I)) |

| Thermal management | Moderate | High copper-plane coupling | High (platform dependent) |

| Multi-phase suitability | Limited | DCR tuning + sensing friendly | Used as backbone stage |

The Result: Bringing Server-Class Stability into EV Autonomy Platforms

- By combining SBP (dynamic transient control) with SEP / SEP-EX (energy backbone), EV compute power rails can achieve:

- Reduced inrush spikes and fewer saturation-induced instabilities

- Improved rail stability for sub-1V SoCs (target window: ±5%)

- Better current sharing in multi-phase VRMs through DCR tuning

- Stronger thermal robustness in high power density compute modules

Key takeaway: EVs are evolving toward rolling data centers. VRM-grade magnetics are becoming mandatory for stable, safe, and scalable compute power.

- Related Products

0.12uH, 102A multiphase buck converter tlvr inductor

SBP110511Q-R12L-LF

0.12uH, 102A SMD TLVR power inductor, in the ever-evolving landscape of data centers, storage systems, graphics cards, and personal computing devices,...

Details Add to List0.15uH, 25.5A SMD High Power Density Flat Wire Power Inductors

SBP75-R15M-LF

Assembly magnetically shielded power inductor 7.2x7.0x5.0mm, utilize the lowest core losses material and clip to instead of the original cooper wire. This...

Details Add to List0.32uH, 50A SMD High Power Density Flat Wire Power Inductors

SBP1308-R32M-LF

Assembly magnetically shielded power inductor 13.5x13x8mm, utilize the lowest core losses material and clip to instead of the original cooper wire. This...

Details Add to List- Related FAQ